Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer

Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer Semi Dull Yarn Manufacturer Polyester Yarn Factory

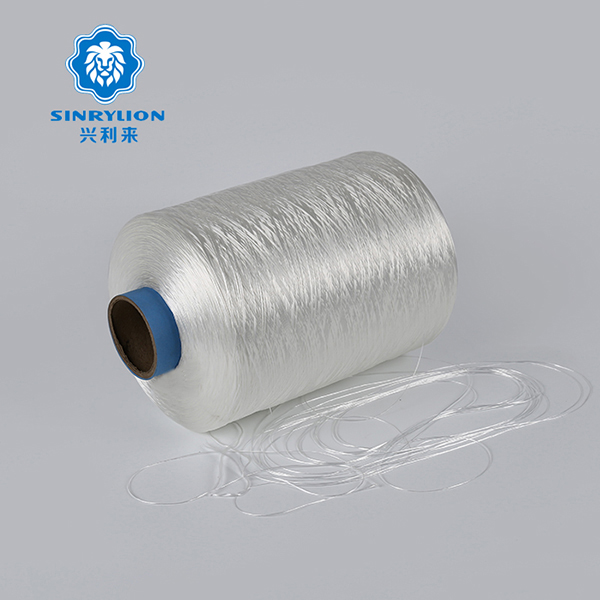

Semi Dull Yarn Manufacturer Polyester Yarn Factory Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply

Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply Good Resilience 0.32mm TPU+TPEE Monofilament Yarn

Good Resilience 0.32mm TPU+TPEE Monofilament Yarn Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use

Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use- All new products

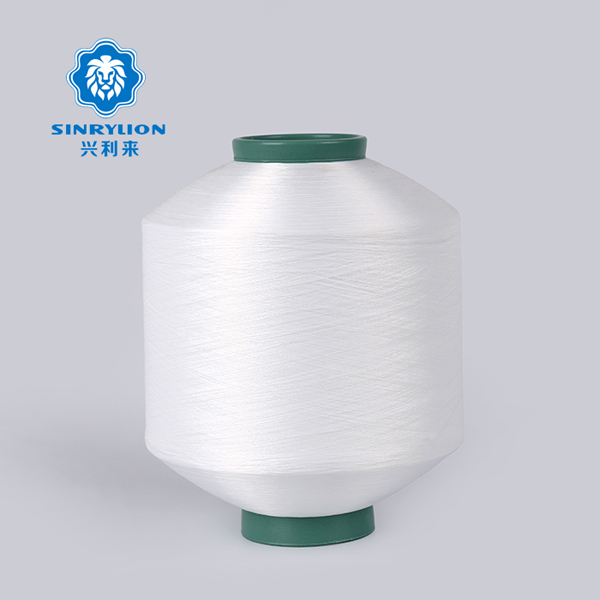

Polyester Twisted Yarn Warp Yarn For Weaving

Send Inquiry

As a key component in textile manufacturing, warp yarns play a vital role, imparting strength, comfort and beauty to a wide range of fabrics, knitwear and weaves.

Sinrylion weaving warp products are carefully designed to meet your various needs. Whether you are looking for soft yarns for fine hand weaving or require hard-wearing and superior strength yarns for industrial textile manufacturing, we have the ideal solution for you.

Sinrylion polyester twisted yarn warp yarn Manufacturer offers a wide selection of yarn counts and fiber types, 50-5000D and 80TPM-1000TPM, allowing you to customize it according to the requirements of your project. Whether it's lightweight cotton, warm wool, or durable polyester, we have something to suit your creative and functional needs.

Product Specification

|

NAME |

FDY 100% polyester warp yarn |

|

RAW MATERIAL |

PET chips and color masterbatches |

|

COLOR |

White |

|

LUSTER |

Bright or semi dull |

|

SPECIFICATION |

500D, 1000D, 2000D, 5000D |

|

TWIST |

80TPM-1000TPM |

|

CERTIFICATIONS |

OEKO-TEX Standard 100 and ISO9001 |

|

SHAPE |

Flat or round |

|

USAGE |

For weaving pattern and knitting and PVC hose |

|

MOQ |

1 kilogram |

|

SAMPLE |

Free |

|

PAYMENT TERM |

By T/T, L/C at sight, Western Union, Paypal or we can negotiate by both of our side. |

|

PACKAGE |

Every cone(1.4kgs) packaging with plastic and around 12 cones in one carton, around 500 cartons a 20ft container. |

|

DELIVERY TIME |

Around 15-20 days after confirming the order. |

|

TYPE OF SHIPPING |

By ship or air or express |

FACTORY VIDEO

PRODUCT VIDEO

Production Process

Material selection: First, select appropriate fiber materials according to needs and product requirements, which can be natural fibers (such as cotton, wool, silk) or synthetic fibers (such as polyester, nylon, polypropylene). The choice of fiber will affect the characteristics and purpose of the warp yarn.

Fiber treatment: After material selection, the fibers need to be treated to remove impurities, loose fibers and other undesirable substances. This step usually includes fiber cleaning, combing, selection and other processing processes to ensure the consistency of fiber quality.

Spinning: After fiber processing, the fibers are fed into the spinning machine for spinning. The purpose of spinning is to convert fibers into continuous yarn. In the spinning machine, fibers are stretched, twisted and straightened to form yarn with a certain strength and twist. Process operations such as yarn twisting, stretching and twist adjustment can also be performed during the spinning process.

Yarn finishing: After spinning is completed, the yarn needs to be finished to ensure the stability and consistency of the yarn quality. The finishing process usually includes operations such as cleaning, soaking, stretching and drying the yarn to eliminate impurities and irregularities in the yarn.

Packaging and Quality Inspection: After finishing, the yarn is wound onto bobbins or spindles and properly packaged. During the packaging process, quality checks are usually performed to ensure that the yarn meets specified quality standards and requirements.

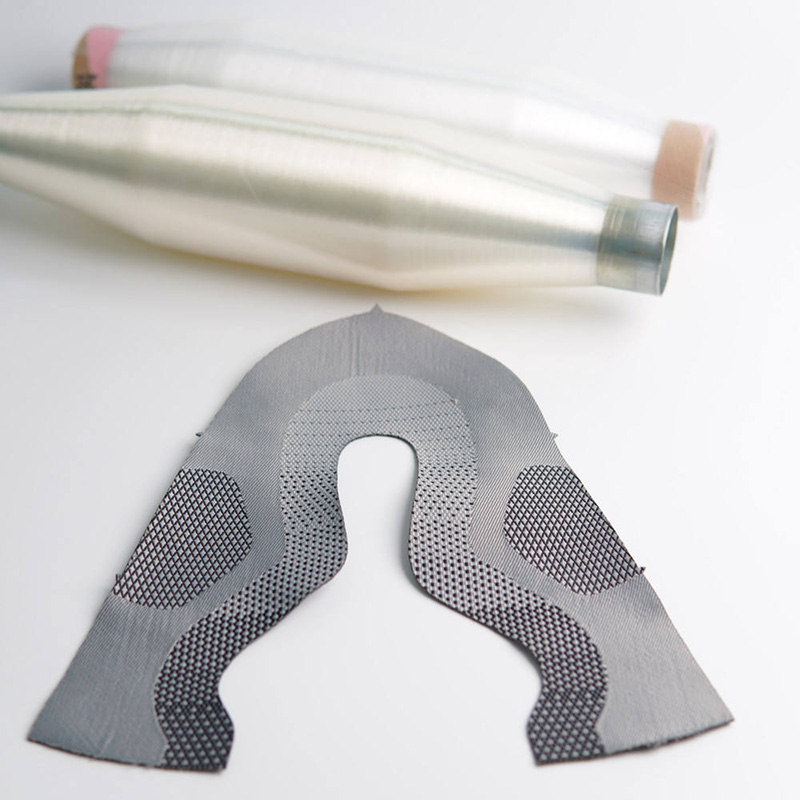

Application of Polyester Twisted Yarn Warp Yarn

Knitwear: Warp yarns are also widely used in the manufacture of knitwear. Knitwear includes various clothing (such as sweaters, socks, hats, etc.) and fabrics (such as knitted fabrics, woven nets, etc.). Warp selection and yarn characteristics have a significant impact on the appearance, elasticity and comfort of knitwear.

Textiles: Warp yarns are used to make various textiles, such as clothing, home textiles (such as bedding, curtains, towels, etc.), fabrics (such as canvas, velvet, denim, etc.), bed sheets, pillowcases, etc. Different specifications and fiber types of yarn can meet the needs of different textiles, such as soft cotton yarn for comfortable clothing and wear-resistant polyester yarn for durable home textiles.

Industrial Textiles: Warp yarns play an important role in the industrial sector and are used in the manufacture of industrial fabrics, filter materials, conveyor belts, ropes, rope nets, industrial sewing threads, etc. Industrial textiles often require high strength, abrasion resistance and durability, so the selection and quality of warp yarns are critical to the performance of industrial products.

Embroidery and Handicrafts: Warp yarns are also widely used in embroidery, hand weaving, handicrafts, etc. Different fiber types of yarn can bring different effects and textures to handmade works. For example, fine and soft silk thread is suitable for exquisite embroidery, and rough and durable hemp thread is suitable for hand weaving.

Advanced textiles: Certain warp yarns are also used to make advanced textiles, such as high-end clothing, high-end home textiles, luxury goods and art. These textiles often require the use of high-quality yarns and fine craftsmanship to achieve a high-end look and quality.

COMPANY PROFILE

JINJIANG XINGLILAI YARNS CO.,LTD was founded in 1983. The group’s total registered capital is 50 million RMB. The headquarters is located in wuli industrial area in Jinjiang. Their foreign partners have throughout Europe, Southeast Asia, South America and other regions. Established a good reputation and won wide praise from customers.

At the same time, the company relies on huge production development and large scale, combined with advanced technology and equipment, which established the foundation on the spinning market.

The company has more than 400 sets of different machines. Like POY spinning equipment, texturing machine, drawing machine, twisting machine, warping machine and so on. Have own R&D center and test center. Their yarns passed the ISO9001 quality system, Global Recycled Standard and Oeko-tex standard 100 certification.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский