Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer

Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer Semi Dull Yarn Manufacturer Polyester Yarn Factory

Semi Dull Yarn Manufacturer Polyester Yarn Factory Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply

Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply Good Resilience 0.32mm TPU+TPEE Monofilament Yarn

Good Resilience 0.32mm TPU+TPEE Monofilament Yarn Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use

Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use- All new products

High toughness PA6 monofilament yarn nylon monofilament yarn for mesh fabric

Send Inquiry

PA monofilament, also known as nylon monofilament or polyamide monofilament, is a synthetic fiber filament formed from adipic acid and hexamethylenediamine or caprolactam through polycondensation reaction and melt spinning. This fiber is commonly known as Nylon, also called Polyamide (PA for short), and is the first synthetic fiber that appeared in the world. Sinrylion is a professional PA monofilament supplier.

Nylon monofilament can be made into elastic yarn, which has the characteristics of good strength and wear resistance. Fabrics made of nylon filaments or short fibers blended or interwoven with other fibers have the characteristics and advantages of various fibers. For civilian use, it can be blended or spun into various medical and knitted products, such as knitted single-tube socks, stretch socks and other wear-resistant nylon socks, nylon gauze, mosquito nets, nylon lace, stretch nylon jackets, various nylon silks or interwoven silks wait. Nylon monofilament and nylon staple fiber are mostly blended with wool or other chemical fiber wool products to make various wear-resistant and durable clothing materials.

Product Specification

|

Name |

Nylon PA Monofilament Y arn |

|

Color |

white |

|

Count |

Custom filament, 0.08mm, 0.11mm, 0.12mm, 0.13mm, 0.14mm, 0.15mm, 0.16mm |

|

Twist |

Custom TPM |

|

Usage |

For elastic cord |

|

MOQ |

1 KG |

|

Sample |

For free |

|

Material |

100% Nylon |

|

Payment Term |

By T/T, L/C at sight, Western Union, Paypal or we can negotiate by both of our side |

|

Package |

Every cone(1.4kgs) packaging with plastic and around 12 cones in one carton, around 500 cartons a 20ft container |

|

Delivery Time |

Around 15-20 days after confirming the order |

|

Type Of Shipping |

By ship or air or express |

PRODUCT VIDEO

PA Monofilament Yarn of Characteristics

Excellent mechanical properties: PA monofilament has high strength and wear resistance, and can withstand large pressure and friction.

Impact resistance: PA monofilament has good impact resistance and can maintain good stability and integrity when impacted.

Wear resistance: PA monofilament has good wear resistance and can maintain its original shape and performance for a long time.

Good low-temperature performance: PA monofilament can maintain good performance in low-temperature environments and is suitable for some occasions that require low-temperature environments.

Good chemical stability: PA monofilament has good chemical stability and can resist the erosion and corrosion of most chemical substances.

Low water absorption: PA monofilament has low water absorption and is not susceptible to moisture and deformation.

Resistant to strong alkali: PA monofilament can withstand the erosion of strong alkali and is suitable for some occasions that require contact with strong alkali substances.

More resistant to weak acid than PA6 monofilament and PA66 monofilament: PA monofilament can maintain good performance in weak acid environment and is more resistant to weak acid than PA6 monofilament and PA66 monofilament.

Renewable material sources: About 60% of PA monofilament comes from plant matter. Renewable material sources make it more popular in industries with large consumption.

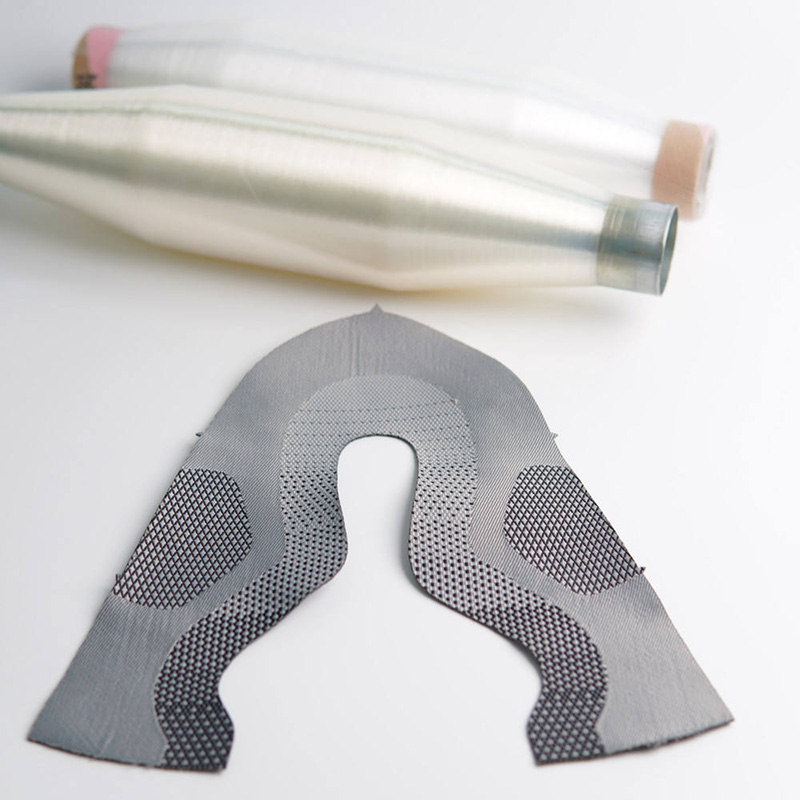

Brush manufacturing: The high elasticity and wear resistance of nylon PA monofilament make it an ideal material for manufacturing various brushes, such as toothbrushes, face brushes, nail brushes, industrial roller brushes, etc. These brushes need to have good elasticity and wear resistance to ensure efficient cleaning results during use.

Filter material: Nylon PA monofilament has high filtration efficiency, easy cleaning, high strength and long service life, so it is widely used in manufacturing various filter materials, such as filters, filters, etc. These filter materials need to be able to effectively filter out impurities and particulate matter while maintaining high throughput and service life.

Sewing thread: The strength and wear resistance of nylon PA monofilament make it an ideal material for making sewing thread. Compared with cotton thread and polyester thread, nylon PA monofilament sewing thread has higher strength and durability, and is suitable for various occasions requiring high-strength sewing.

Industrial parts: Because nylon PA monofilament has excellent mechanical properties, heat resistance and electrical properties, it is widely used in manufacturing various industrial parts, such as electrical accessories, automobile parts, mechanical parts, etc. These parts need to be able to withstand greater pressure and friction while maintaining good stability and integrity.

Sports equipment: The high strength and high toughness of nylon PA monofilament make it an ideal material for manufacturing sports equipment, such as fishing lines, fishing nets, tents, backpacks, etc. These sports equipment need to be able to withstand large pulling forces and impact forces while maintaining good durability and comfort.

PA Monofilament Yarn of Production Process

Slice feeding and extrusion: PA6 dry slices are unpacked and added to the feeding hopper, then controlled by a pneumatic valve to enter the intermediate silo, and continuously fed into the screw extruder for melting, mixing and metering. The screw extruder is equipped with a heating capacity device, which adjusts the temperature zone according to process requirements. The screw is driven by an AC motor, and the extrusion pressure is controlled by frequency conversion to meet the requirements.

Spinning: The melt enters the distribution pipe under the pressure of the screw head and is evenly sent to each spinning position according to the equidistant principle. Each spinning position is equipped with a high-precision melt metering pump. The melt is accurately measured by a metering pump, sent evenly to each spinning component, filtered through metal sand and filters, and sprayed into filaments from the spinneret. The molten filaments emerging from the spinneret are cooled by laminar side blowing in an optimized side blowing unit. The filaments become solid, the fiber structure undergoes crystallographic orientation and becomes macromolecules. The oil injection device uses a high-precision oil injection pump to supply oil, so that the thread has the oil content required for the process. Both the spinning box and the melt tube are insulated to a certain temperature.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский