Why Polyester Twisted Yarn Is the First Choice of Webbing Manufacturers

What exactly is polyester twisted yarn? ——Starting from the yarn structure

In the manufacture of webbing, the choice of materials directly affects the strength, appearance and service life of the finished product. In recent years, Polyester Twisted Yarn has gradually become the preferred material for webbing factories, not only because of its excellent physical properties, but also because it can meet the dual needs of modern webbing for functionality and stability.

We can understand the uniqueness of polyester twisted yarn from the following aspects:

The essence of twisting

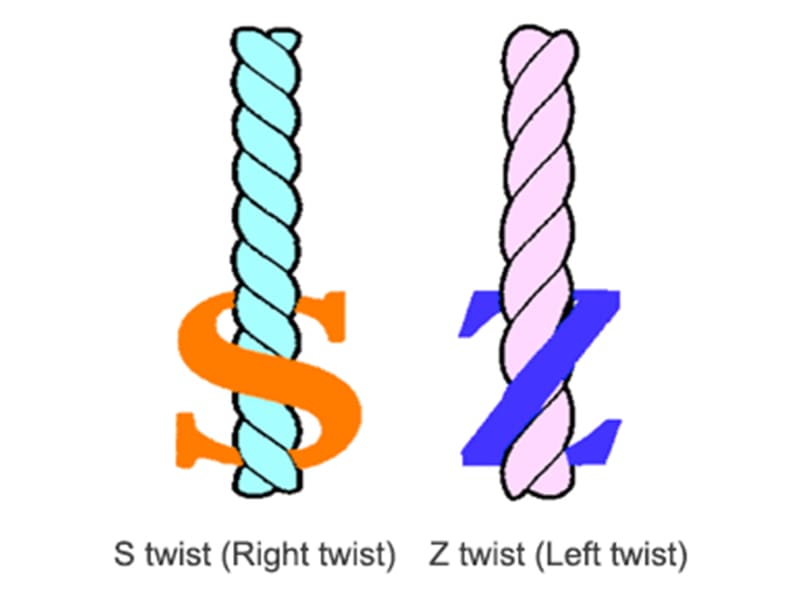

The so-called "twisting" is to rotate polyester filaments or staple fibers in a certain direction so that the fibers are entangled with each other, thus forming a tighter and stronger structure.

- ● There are two types of twist directions: S twist and Z twist

- ● The twist determines the tightness and elasticity of the yarn

Through twisting, the overall structure of the yarn is more stable, effectively avoiding the problems of unraveling, breaking or pilling.

Structural characteristics of polyester twisted yarn

Polyester itself has good tensile strength, wear resistance and weather resistance. After twisting, these advantages are further enhanced. Its core features include:

- ● Strength improvement: twist enhances the yarn's resistance to tension

- ● Excellent anti-hairy performance: a tighter structure reduces pilling during friction

- ● Strong dimensional stability: the twisted yarn after heat setting is stable in subsequent weaving and dyeing

Comparison with ordinary polyester yarn

|

Comparison Dimensions |

Ordinary polyester yarn |

Polyester twisted yarn |

|

Structural density |

Loose |

Closer |

|

Strength performance |

generally |

Stronger tensile strength |

|

Hairiness control |

Easy to pilling |

Smooth surface, not easy to pilling |

|

Finished product stability |

Easy to deform |

More stable after heat setting |

|

Applicable scenarios |

Clothing fabrics |

Functional webbing (seat belts, backpack straps, etc.) |

Why is it suitable for webbing manufacturing?

Webbing products are mostly used in functional occasions such as load-bearing, traction, fixation, and restraint, and have extremely high requirements for the physical properties of the material. The twisted polyester yarn not only meets the requirements of tensile resistance, wear resistance and corrosion resistance, but also brings good stiffness and elasticity. It is balanced in appearance and practicality, and has become one of the irreplaceable core materials of the ribbon factory.

Comprehensive analysis of advantages: How polyester twisted yarn helps high-performance ribbons

Ribbon manufacturing should not only focus on function, but also consider efficiency and consistency. Polyester twisted yarn meets these requirements in multiple dimensions.

High strength and low elasticity: safety and performance

Twisting treatment significantly improves the structural strength of polyester yarn, making it less likely to break during stretching and less likely to deform excessively. This low elasticity feature is especially important for load-bearing ribbons, for example:

- ● Luggage straps need to maintain the same size when tightened

- ● Industrial binding straps require long-term tension without deformation

- ● Outdoor traction ropes must have sufficient strength and weather resistance

Tight surface, improved wear resistance

Polyester twisted yarn has a smoother surface and a tighter structure. After being woven into a ribbon, it is not easy to pill, drop fibers or wear. In high-friction frequency applications, such as mountaineering harnesses, pet ropes or outdoor bag straps, its durability is far superior to ordinary yarn products.

Good heat setting, improving the consistency of finished products

The yarn with stable twist can maintain good consistency when set at high temperature, making the finished ribbon more standardized in appearance, width and feel. This consistency is very important for ribbon brands that pursue high quality.

Adapt to various processes

Whether it is woven, knitted or jacquard, polyester twisted yarn can be flexibly adapted. The combination of different twists and counts can achieve the functional requirements of different ribbons. For example:

- ● Jacquard ribbons prefer to use medium twist yarns to ensure clear patterns

- ● High-strength load belts require higher twist to improve the overall load-bearing capacity of the ribbon

Why do professional ribbon factories prefer reliable Polyester Twisted Yarn Manufacturers?

When choosing a yarn supplier, most ribbon manufacturers prefer to cooperate with experienced and technically reliable Polyester Twisted Yarn Manufacturers. The reasons are as follows:

Stable quality system

Mature twisted yarn manufacturers have a complete quality inspection system, including:

- ● Automated tension control equipment to ensure uniform twist

- ● Online inspection system to identify problems such as broken wires and loose twist

- ● Pre-delivery strength and wear resistance testing to ensure consistent performance of each batch of yarn

Professional customization capabilities

Ribbon factories usually face diverse needs, such as special colors, directional twist, functional requirements, etc. High-quality suppliers can quickly adjust production parameters according to customer requirements, and even support sample proofing and small batch customization, and flexibly adapt to market demand.

Quick response and delivery guarantee

Ribbon factories often receive short-cycle, fast-delivery orders, and have high requirements for the response speed of raw material supply. Polyester Twisted Yarn manufacturers with large-scale production capacity and fast logistics system can complete orders, production and shipment in a short time to avoid affecting customer delivery.

Technical support and after-sales service

Some professional manufacturers are also equipped with technical service teams to help customers solve problems such as webbing pilling, webbing breakage, uneven tightness, etc. This kind of cooperation is not only about raw material procurement, but also a guarantee of production efficiency and yield rate.

Are you looking for affordable polyester twisted yarn? You have come to the right place. We are committed to providing our customers with quality products and the best value. Your satisfaction is our motivation. Send an email to janekwok@xll-group.com today and our manufacturer will be happy to serve you.

|

Contact Us |

Email: janekwok@xll-group.com |

Whatsapp: +86-15980572980 |

Practical Guide: How to Choose High-Quality Polyester Twisted Yarn

Choosing polyester twisted yarn seems simple, but to ensure the performance and quality of the webbing, you also need to master some practical skills.

Clarify the usage scenario and match the performance parameters

Different application scenarios have different requirements for the count, twist, color, and functionality of the yarn. It is recommended to determine the following parameters according to the purpose of the webbing:

- ● Count: affects the thickness and softness of the webbing

- ● Twist (TPM): determines strength and elasticity

- ● Number of strands: multi-strand synthesis can improve tension and wear resistance

- ● Whether heat setting is required: It is recommended to choose a fixed product for outdoor scenes

Check the appearance and twist uniformity of the yarn

High-quality twisted yarn should have a smooth surface, no obvious hairiness, uneven thickness, and too many knots. The twist should be uniform and not "loose", which can be judged by the feel and winding density.

Request relevant certification and test data

Before purchasing, the supplier should be asked to provide the following information:

- ● Quality test report (breaking strength, elongation, etc.)

- ● Environmental certification (such as Oeko-Tex, GRS, etc.)

- ● Traceable production batch number for later traceability and quality control

Proofing test cannot be ignored

Before placing a formal order, the sample machine should be used for trial spinning to observe the yarn's fit on the webbing equipment, the fabric surface effect, the shrinkage rate and the shaping performance to avoid large batch errors.

Application and Trend: Future Potential of Polyester Twisted Yarn in the Webbing Industry

As the demand for webbing market continues to diversify, polyester twisted yarn is also evolving, showing the following major trends:

The trend of sustainable materials is obvious

More webbing brands are beginning to choose regenerated polyester twisted yarn (rPET Twisted Yarn) to reduce carbon footprint and meet ESG policy requirements. High-quality Polyester Twisted Yarn Manufacturers are increasing their investment in R&D and production capacity of GRS-certified products.

Functional yarns are becoming increasingly popular

The market demand for antibacterial, UV-resistant, flame-retardant and other functions is increasing. Through masterbatch modification or post-processing processes, twisted yarns are moving towards "multifunctional integration" and serving special fields such as medical, military, and security.

Flexible customization and digital production have become mainstream

Advanced manufacturers are promoting intelligent twisting systems, and through digital twist control, online monitoring and automatic packaging, they can achieve efficient and flexible customized production to meet the needs of rapid brand iteration.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский