Sinrylion: A Trustworthy Polyester Twisted Yarn Manufacturer

Basic knowledge of polyester twisted yarn: What is it? Why is it so important?

As an important basic material in the textile industry, polyester twisted yarn has the following key characteristics and functions:

What is polyester twisted yarn?

- ● Definition: Polyester twisted yarn refers to a multi-strand winding yarn made of polyester filament or staple fiber through a twisting process.

- ● Features of raw materials: Polyester fiber has the advantages of high strength, good wear resistance, easy washing and quick drying, and chemical corrosion resistance. It is one of the most widely used synthetic fibers.

The role of twisting process

- ● Enhance yarn strength: Twisting makes the fibers tightly entangled, greatly improves the overall strength of the yarn, and avoids breakage and looseness.

- ● Improve elasticity and stability: Twisting gives yarn elasticity, stable fabric shape, and reduces deformation, wrinkling and pilling.

- ● Improve fabric performance: Twisted yarn is more suitable for dyeing and printing, and the color is uniform and lasting.

Why is polyester twisted yarn so important?

- ● Basic raw materials: As the basic yarn of various fabrics, it directly determines the mechanical properties and comfort of the fabric.

- ● Widely used: covering clothing, home textiles, industrial fabrics, functional textiles and many other fields.

- ● Supporting the development of the textile industry: high-quality twisted yarn meets the ever-increasing market demand and is an important driving force for the technological progress of the textile industry.

Current status of industry development

- ● Technology upgrade: automated and intelligent twisting equipment improves production efficiency and product quality.

- ● Environmental protection trend: green manufacturing concept drives the promotion and application of recycled polyester twisted yarn.

- ● Market demand growth: consumers' dual demands for performance and environmental protection drive twisted yarn product innovation.

Analysis of twisting process: S twist and Z twist and their influence

The twisting process is the core link in the production process of polyester twisted yarn. By rotating and winding multiple fibers in a certain direction and twist, an overall stable yarn is formed. Two important concepts in the twisting process are twist direction and twist degree.

Twist direction: the difference between S twist and Z twist

Twist direction is the direction of yarn rotation, which is usually divided into S twist and Z twist:

- ● S twist: The direction of yarn rotation is the same as the direction of the middle diagonal line of the English letter "S", that is, clockwise rotation. S twisted yarn has a tighter structure and higher strength, which is suitable for fabrics with high load and durability requirements.

- ● Z twist: The direction of yarn rotation is the same as the direction of the middle diagonal line of the English letter "Z", that is, counterclockwise rotation. Z twisted yarn is softer and the fabric feels better. It is often used in leisure, home textiles and other products with high comfort requirements.

Reasonable selection of twist direction not only affects the performance of the yarn itself, but also has a profound impact on the feel and durability of the fabric. Many fabrics achieve the best balance between strength and softness by properly matching S-twist and Z-twist yarns.

Importance of twist

Twist refers to the number of twist turns per unit length of the yarn, usually expressed as "twists/meter". Appropriate twist is a key factor in ensuring the strength and elasticity of the yarn:

- ● Twist is too low: the yarn structure is loose, the strength is insufficient, and the fabric is easy to break and deform.

- ● Twist is too high: the yarn is too tight, the yarn is hard and brittle, and the fabric feels poor.

Sinrylion uses advanced CNC twisting equipment, combined with digital tension monitoring technology, to accurately control the twist and twist direction to optimize the yarn performance. Through strict management of the twisting process, sinrylion ensures that each batch of products meets the high standards of customers in terms of strength, elasticity and stability.

Sinrylion: A 40-year manufacturing expert in polyester twisted yarn

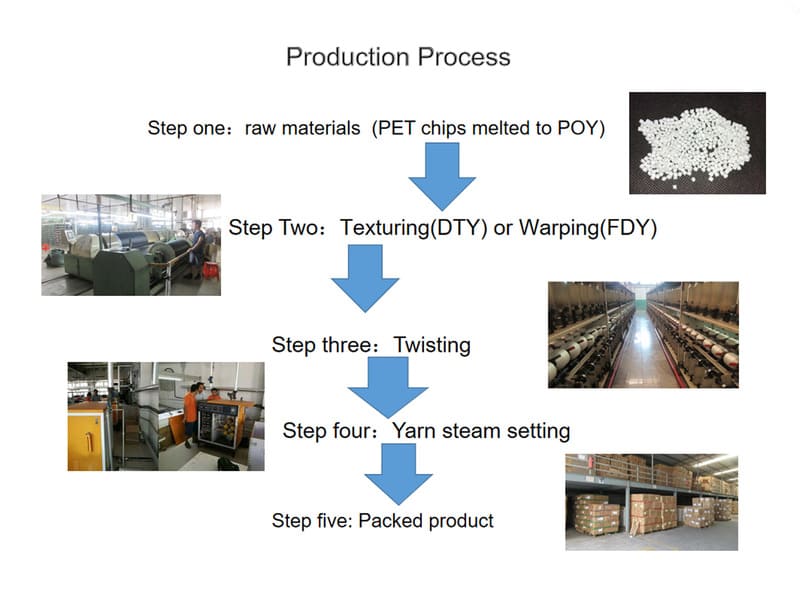

Since its establishment in 1983, sinrylion has focused on the research and development and manufacturing of polyester twisted yarns, and has accumulated rich industry experience and profound technical strength. The company occupies a vast area and is equipped with more than 400 advanced automation equipment to achieve full-process automated production of polyester twisted yarns from raw yarn pretreatment, twisting to steam setting and packaging.

Advanced equipment and intelligent manufacturing

Sinrylion introduces internationally leading CNC twisting machines and intelligent testing equipment, combined with the manufacturing execution system (MES) for real-time collection and analysis of production data. Digital technology is used to monitor key production parameters such as tension, twist, temperature, etc. to ensure process stability and product consistency. The application of steam setting technology can effectively improve the dimensional stability of yarn and reduce the yarn breakage rate and deformation rate.

Strict quality management system

The company has established a complete quality management system, implemented ISO9001 international quality standards, and passed Oeko-Tex Standard 100, GRS (Global Recycling Standard) and other authoritative certifications. Equipped with modern testing instruments, raw material inspection, process inspection and finished product quality control are implemented to ensure that each batch of polyester twisted yarn meets international high standards.

Continuous R&D and innovation

Sinrylion has a professional R&D team, continuously optimizes polyester yarn formula and twisting process, and is committed to developing functional yarns, such as antibacterial, UV protection, flame retardant and other diversified products. At the same time, it actively develops recycled polyester twisted yarn to respond to the global green environmental protection trend.

Customer first and customized services

The company focuses on customer needs and provides flexible customization services, including yarn specifications, twist, color and functional additives, to meet the personalized needs of customers in different industries. The perfect after-sales service system ensures that customers receive all-round support during the production and application process.

Are you looking for affordable polyester twisted yarn? You have come to the right place. We are committed to providing our customers with quality products and the best value. Your satisfaction is our motivation. Send an email to janekwok@xll-group.com today and our manufacturer will be happy to serve you.

|

Contact Us |

Email: janekwok@xll-group.com |

Whatsapp: +86-15980572980 |

Main application areas and performance advantages of polyester twisted yarn

The polyester twisted yarn products produced by sinrylion have stable performance and complete specifications, and are widely used in many important fields:

- ● Sportswear field:Sportswear has high requirements for the strength, elasticity and wear resistance of fabrics. Sinrylion polyester twisted yarn has high strength and excellent elasticity. The woven sportswear has good wear resistance and moisture absorption and perspiration function, while maintaining lightness and softness to enhance the wearing experience.

- ● Home textile field:Home textile products such as bedding, sofa fabrics and curtains require yarns to be washable and durable. Sinrylion polyester twisted yarn has high color fastness, the fabric is wrinkle-resistant and not easy to deform, which extends the service life of home textile products while ensuring a comfortable feel.

- ● Industrial fabrics:Industrial textiles such as seat belts, filter cloths, conveyor belts, etc. require yarns with extremely high strength and durability. Sinrylion produces high-strength twisted yarns according to industrial standards to ensure the safety and stability of industrial products.

- ● Functional textiles:As the demand for functional textiles grows, Sinrylion has developed a variety of functional polyester twisted yarns such as antibacterial, UV protection, and antistatic, which are widely used in high-end markets such as medical protection and outdoor equipment to meet diverse performance requirements.

Product performance advantages

- ● High mechanical strength: Enhances the wear and tear resistance of fabrics.

- ● Excellent elasticity and stability: The fabric is more wrinkle-resistant and has good elastic recovery.

- ● Environmental safety: Meets international environmental and safety standards and is suitable for functional textiles.

- ● Multi-specification selection and customization capabilities: Meet different textile processes and product positioning.

Future Trends: Sustainable Twisted Yarn Technology and Intelligent Manufacturing

Facing the trend of green transformation and digital upgrading of the global textile industry, sinrylion actively plans for future development directions:

Green and Sustainable Development

Sinrylion actively promotes the use of recycled polyester raw materials to reduce dependence on petrochemical resources. The production process is continuously optimized to reduce energy consumption and emissions, and cooperate with wastewater and waste gas treatment facilities to achieve environmentally friendly production goals. The company has been approved for green certifications such as GRS to promote yarn recycling and green supply chain construction.

Functional Yarn Innovation

With the upgrading of consumption, there is a strong demand for functional yarns such as antibacterial, flame retardant, UV protection, and anti-static. Sinrylion continues to invest in research and development, combining nanotechnology with environmentally friendly additives to create high-performance twisted yarns to meet new needs in multiple fields such as medical, outdoor, and home textiles.

Intelligent Manufacturing and Digital Factory

Through the Industrial Internet of Things (IIoT), big data, and artificial intelligence technologies, sinrylion realizes intelligent monitoring, predictive maintenance, and automatic adjustment of production equipment to improve production efficiency and product consistency. Intelligent logistics and digital supply chain management enhance the ability to respond to market changes.

Market globalization and customized services

In the future, the market will have greater demand for personalized, high value-added products. Sinrylion will continue to optimize its customized service system, respond quickly to customer needs, and help customers seize market opportunities.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский