Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer

Professional Polyester Textured Yarn and Fancy Fur Yarn Manufacturer Semi Dull Yarn Manufacturer Polyester Yarn Factory

Semi Dull Yarn Manufacturer Polyester Yarn Factory Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply

Sinrylion Polyester Twisted Yarn Manufacturer Raw White Supply Good Resilience 0.32mm TPU+TPEE Monofilament Yarn

Good Resilience 0.32mm TPU+TPEE Monofilament Yarn Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use

Polyester Raw White DTY Dyeable Tube 150D/120T For Sewing Thread Use- All new products

Wholesale Recycled Polyester DTY For Woven Label

Send Inquiry

Sinrylion Recycled Polyester DTY Yarn Manufacturer

Recycled PET fabric is a new type of environmentally-friendly recycled fabric whose yarn is from discarded mineral water bottles, It is also made into a Coke bottle and is also known as RPET fabric. Recycle polyester dty yarn uses polyester chips (PET) as raw material and undergoes a series of processing techniques, such as melt polymerization, spinning, false twist deformation, etc., to produce synthetic fibers with high elasticity, high strength, and high wear resistance.

This product is very popular in foreign countries, especially developed countries in Europe and America, because it is waste recycling. It is widely used in mountaineering bags, bags, bags, bags, bags, clothing, briefcases, fashion bags, storage boxes, bundle pockets, gift bags, handbags, shopping bags, and more. The Coke bottle "recycled staple fiber" can be twisted into yarn and then woven into fabric to be manufactured into various other products.

Product Specification

|

Name |

Recycle Polyester DTY Yarn |

|

Raw Material |

PET chips and color masterbatches |

|

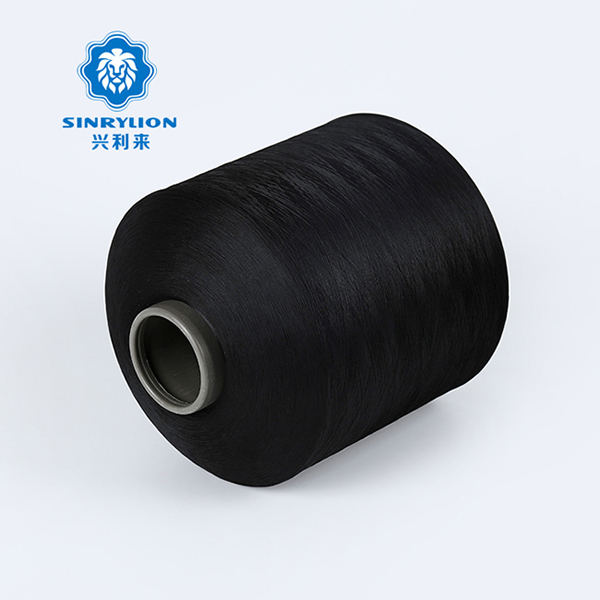

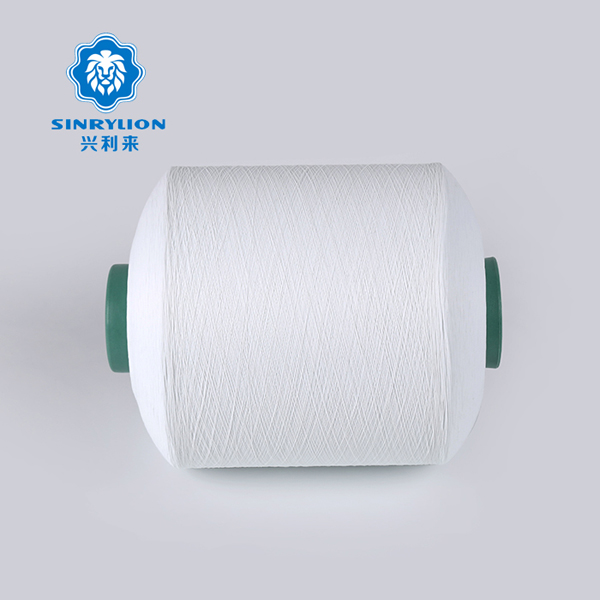

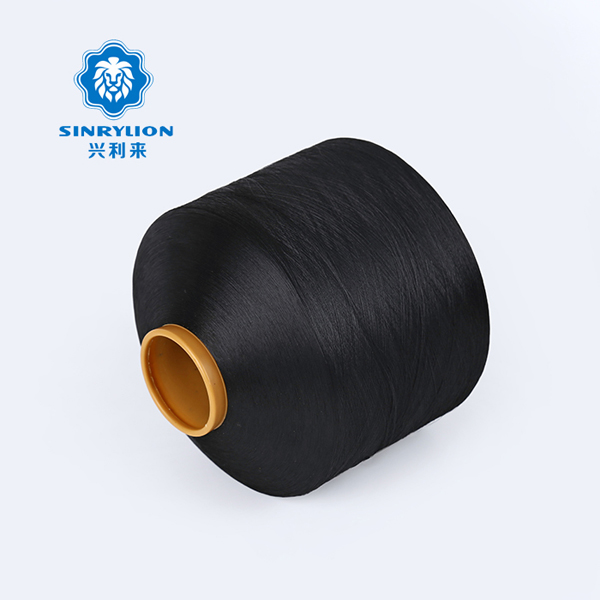

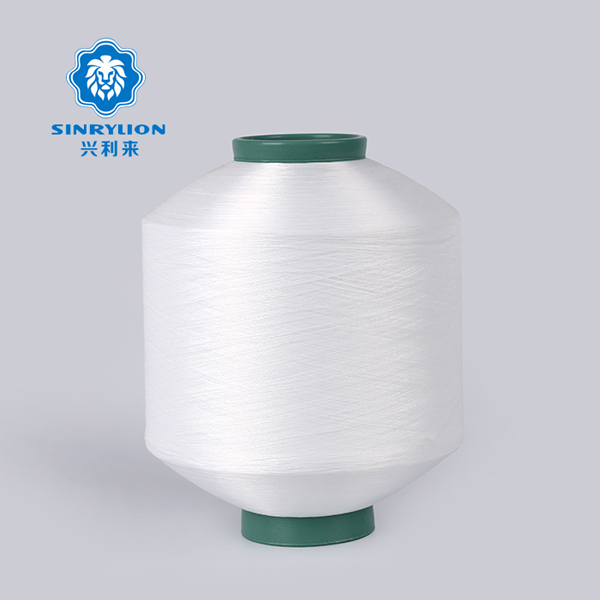

Color |

Dope dyed black or raw white |

|

Luster |

Semi dull, Full dull |

|

Specification |

50D-600D |

|

Certifications |

OEKO-TEX Standard 100 and ISO9001 |

|

Shape |

Flat or round |

|

Usage |

For weaving pattern and knitting |

|

MOQ |

1 kilogram |

|

Sample |

Free |

|

Package |

Every cone(1.4kgs) packaging with plastic and around 12 cones in one carton, around 500 cartons a 20ft container |

|

Delivery Time |

Around 15-20 days after confirming the order |

|

Type of Shipping |

By ship or air or express |

|

Yarn Count/Daniel/Luster/Twist/Colors Specifications Can Be Customized |

|||

|

Yarn Style |

Specification |

Luster |

Color |

|

Polyester Twisted Yarn |

FDY:50D-75D/36F/ 150TPM-350TPM |

SD/TBR |

Raw White /Black |

|

DTY:50D-600D/24F-192F/ 80TPM-800TPM |

Raw White |

||

|

Provide Twisting Service as Customer Needed: From 50D~5000D/80TPM~1000TPM |

|||

|

Recycled

Polyester Yarn |

FDY:50D-150D/7F-36F/ 0 TPM-800TPM |

SD/TBR |

Raw White /Black |

|

DTY:50D-600D/24F-192F/ 0 TPM-120TPM |

FD/SD/TBR |

||

|

Provide Twisting Service as Customer Needed: 80TPM~1000TPM |

|||

|

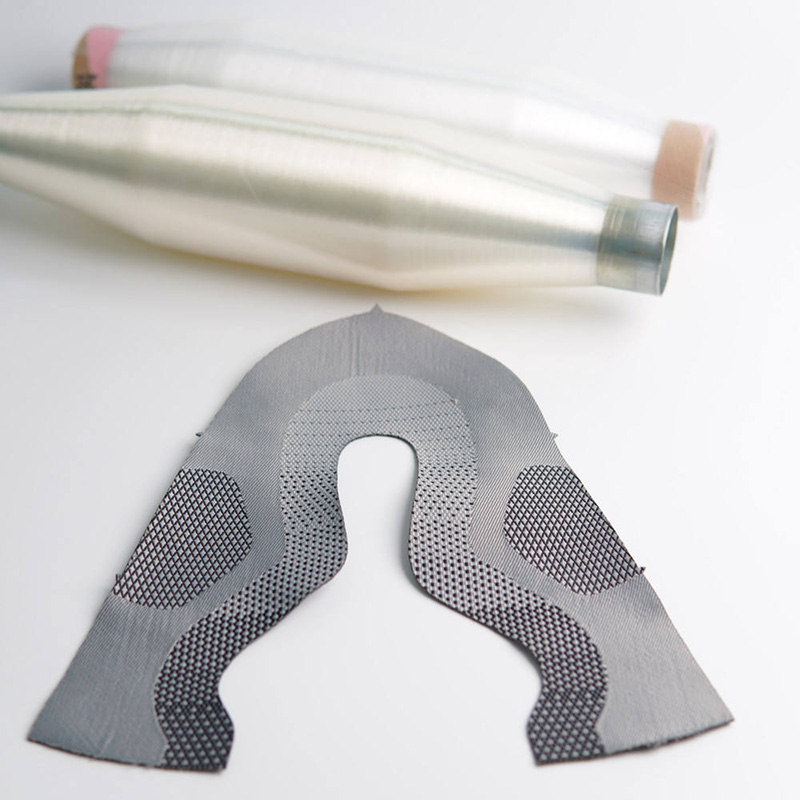

Woven Label Yarn |

FDY:50D-150D/24F-48F/ 600TPM-800TPM |

SD/TBR |

Raw White /Black/Optical White |

|

DTY:50D-600D/24F-192F/ 120TPM |

SD/FD |

Optical White /Black |

|

|

Provide Warping Service to Warp on the Beam |

|||

|

Functional polyester yarn |

Flame retardant FDY: 50D-100D/36F/600TPM-800TPM |

SD/TRB |

RW/BK/DYED |

|

Flame retardant DTY: 50D-600D/24F-192F/120TPM |

RW/BK/DYED |

||

|

UV resistant DTY: 50D-600D/24F-192F/120TPM |

|||

Factory Video

Product Video

Production Process

Raw material preparation:Mix and stir raw materials such as PET and PBT to form a uniform mixture for the next step of polymerization.

Polymerization: Through the reaction of high temperature and high pressure, the raw material molecules are polymerized to form a polymer. Polymerization generally adopts a continuous reaction method, that is, the liquid polymer that has been partially polymerized in advance is added to the feeder, and monomers are continuously added to maintain the reaction at a certain temperature and pressure until the end of the reaction.

Filtration, purification, dehydration and other processes.

Spinning: After the polymer is heated to a semi-melted state, it is evenly drawn into filaments through the nozzle holes, and is stretched during the drawing process to achieve a stretching ratio of more than 1,500 times.

Twist: The fibers are twisted according to a certain degree of twist and twist to form a suitable yarn.

Sinrylion Advantages

1. We are a yarn manufacturer with more than 40 years experience.

2. We have more than 400 sets of different machines. Like POY spinning equipment, texturing machine, drawing machine, twisting machine, warping machine and so on. Among them, we have about two hundred twisters.

3. We can produce twenty tons of yarn per day.

4. Our products passed the ISO9001quality system and Oeko-tex Standard 100 ecological textile certification.

5. We produce high quality yarns.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский