Polyester Twisted Yarn Manufacturers: Sinrylion 40 Years Experience

Sinrylion: 40 Years Dedicated to Polyester Twisted Yarn Manufacturing

Founded in March 1983 in Jinjiang, Fujian, Sinrylion (Jinjiang Xinglilai Yarn Co., Ltd.) has grown into one of China’s leading Polyester twisted yarn manufacturers. Over four decades, Sinrylion has consistently delivered high-quality yarn products, earning trust and long-term cooperation from clients worldwide.

- ● Solid Industry Reputation: Today, Sinrylion partners with clients across Fujian, Guangdong, Zhejiang, Hong Kong, as well as Europe and Southeast Asia. With stable quality and timely delivery, it has built a strong reputation in both domestic and international markets.

- ● Diverse Product Portfolio: Sinrylion manufactures a wide range of yarns, including Polyester twisted yarn, recycled yarn, nylon twisted yarn, diamond yarn, monofilaments, blended yarns, fancy yarns, and ES fibers. These are widely applied in trademarks, woven fabrics, knitting, and webbing.

- ● Robust Production Capacity: The company operates more than 400 sets of equipment, including about 200 two-for-one twisters. With a daily capacity of 20 tons, it produces over 2,000 tons of high-grade polyester yarn and 8,000 tons of regular polyester yarn annually.

- ● International Certification: All products comply with ISO9001 Quality Management System, Oeko-Tex Standard 100, and the Global Recycled Standard (GRS), guaranteeing both quality and environmental responsibility.

With its strong foundation, advanced technology, and global market presence, Sinrylion continues to stand out among Polyester twisted yarn manufacturers.

Characteristics and Wide Applications of Polyester Twisted Yarn

Polyester twisted yarn is a critical material in today’s textile industry due to its versatility, durability, and cost efficiency. By applying varying levels of twist (from 80 TPM to 1000 TPM), polyester yarn can be adapted for multiple end uses.

- ● Durability: Polyester fibers are known for their high tensile strength and resistance to wear, making twisted yarn suitable for demanding textile applications.

- ● Elasticity and Shape Retention: Twisting improves yarn elasticity and helps fabrics maintain their shape, which is especially valued in knitting and webbing industries.

- ● Dyeability and Color Variety: Sinrylion produces over 1,000 vivid color shades, providing manufacturers with consistent and stable hues that meet fashion and branding requirements.

- ● Versatile Applications: From clothing labels and woven fabrics to sportswear and industrial webbing, Polyester twisted yarn offers reliable performance. Its adaptability makes it the preferred choice for manufacturers seeking efficiency without compromising quality.

This combination of mechanical strength, aesthetic versatility, and cost-effectiveness explains why demand for Polyester twisted yarn continues to rise worldwide.

Are you looking for affordable polyester twisted yarn? You have come to the right place. We are committed to providing our customers with quality products and the best value. Your satisfaction is our motivation. Send an email to janekwok@xll-group.com today and our manufacturer will be happy to serve you.

|

Contact Us |

Email: janekwok@xll-group.com |

Whatsapp: +86-15980572980 |

Sinrylion’s Production Advantages and Technical Expertise

Sinrylion’s technical advantage comes from both scale and precision. With over 400 advanced machines, including POY spinning equipment, draw texturing machines, two-for-one twisters, and warping machines, Sinrylion has established a robust manufacturing system.

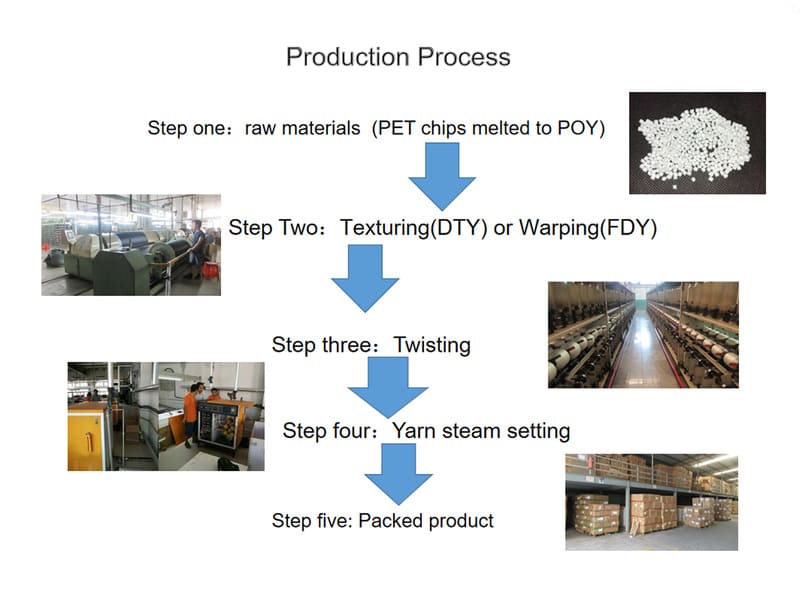

Step-by-step production process:

- ● Raw Material Preparation – High-quality POY (Partially Oriented Yarn) is carefully selected as the base material.

- ● Draw Texturing – The yarn is stretched and textured to improve uniformity and elasticity.

- ● Twisting – With more than 200 two-for-one twisters, Sinrylion ensures precision twisting from 80 TPM to 1000 TPM, depending on customer requirements.

- ● Heat Setting – Stabilizes the twist and enhances the yarn’s dimensional stability.

- ● Winding & Packaging – The yarn is wound into uniform packages, ensuring consistent quality and readiness for global shipment.

Alongside production, Sinrylion maintains its own independent R&D center and testing laboratory, ensuring continuous innovation and rigorous quality control. This blend of technology and expertise gives the company a competitive edge among Polyester twisted yarn manufacturers.

Reasons to Choose Sinrylion as Your Partner

Choosing the right supplier is critical for textile manufacturers. Here’s why Sinrylion stands out:

- ● Over 40 Years of Experience: A long history ensures stability, know-how, and accumulated expertise.

- ● Advanced Production Facilities: With over 400 machines and a 20-ton daily output, Sinrylion guarantees both quality and timely delivery.

- ● Flexible Orders: The company accepts both bulk and small-volume orders, offering free samples to support customer development.

- ● Certified Quality: Compliance with ISO9001, Oeko-Tex Standard 100, and GRS certifications ensures international trust and market access.

- ● Innovation-Driven: Through its R&D center, Sinrylion continually develops new yarn types, including eco-friendly recycled options.

For customers seeking a reliable partner in Polyester twisted yarn production, Sinrylion offers both scale and personalized service.

Sinrylion’s Quality Control and International Certifications

Quality is the cornerstone of Sinrylion’s long-term success. The company has built a multi-level quality control system to ensure every spool of yarn meets international standards.

- ● ISO9001 Quality Management System: Guarantees consistency in production and process optimization.

- ● Oeko-Tex Standard 100 Certification: Ensures yarns are safe, non-toxic, and eco-friendly, meeting strict European textile safety standards.

- ● Global Recycled Standard (GRS): Confirms that recycled yarn products are traceable, sustainable, and environmentally responsible.

Additionally, Sinrylion’s testing center carries out inspections on strength, colorfastness, uniformity, and twist stability before products are shipped. This commitment to quality enables Sinrylion to remain a trusted name among Polyester twisted yarn manufacturers worldwide.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский