How to Choose the Best Polyester Twisted Yarn Manufacturers for Your Business

2025-08-18

Evaluating the Quality and Performance of Polyester Twisted Yarn

Before selecting a polyester twisted yarn manufacturer, companies must first assess product quality. Yarn quality not only affects weaving efficiency but also directly determines the stability of the finished product and the end-consumer experience.

- ● Key Quality Standards: Breaking strength is a core quality indicator for yarn during weaving and use. Insufficient strength can easily lead to yarn breakage on the loom, increasing production costs. Color fastness determines whether the yarn will easily fade during dyeing or use, which is a crucial guarantee for the final product to enter the market. Uniformity is also critical. Inconsistent yarn thickness can cause defects in the fabric and affect the scrap rate of the entire batch.

- ● Testing Methods and Tools: Professional polyester twisted yarn manufacturers typically have laboratories that use equipment such as twist meters, color fastness testers, and single yarn strength testers to test yarn performance. Before purchasing, companies can request test reports from suppliers to verify quality and performance.

- ● Factors Affecting Performance: Raw materials, processes, and equipment all contribute to yarn performance. High-grade polyester or recycled polyester raw materials can improve yarn stability; precise twisting processes ensure consistent yarn twist; and modern two-for-one twisting machines and automated production lines help maintain production stability. Understanding these factors can help companies determine whether a supplier has the ability to provide high-quality yarn.

How to Assess the Production Capacity and Technical Level of Polyester Twisted Yarn Manufacturers

Production capacity and technical level are important factors in evaluating supplier reliability. When selecting a manufacturer, companies should thoroughly examine the following aspects:

- ● Factory Size and Equipment: Large-scale factories with advanced equipment can typically handle orders of varying batch sizes and maintain consistent yarn quality. Modern equipment also improves production efficiency and reduces errors caused by human intervention.

- ● Production Capacity and Supply Stability: Before placing large orders, companies should confirm whether the manufacturer has stable production capacity, especially whether they can deliver on time during peak season.

- ● R&D and Testing Capabilities: Manufacturers with their own R&D and testing centers can monitor quality in real time during the production process and develop functional yarns, such as wear-resistant and eco-friendly yarns, tailored to customer needs.

- ● Technical Experience and Process Accumulation: Companies with a long history of producing twisted polyester yarns have greater experience in twist control and uniformity assurance, making them more reliable when handling complex orders.

Cost, Supply, and Flexibility: Key Considerations in Enterprise Procurement

When selecting suppliers, companies should not only consider unit price but also comprehensively consider cost, delivery time, and flexibility.

- ● Cost Structure:The cost of twisted polyester yarn is typically composed of three aspects: raw material, production, and transportation. Raw material price is often the most significant component, as different grades of polyester chips or recycled polyester directly affect yarn performance and price. The production process involves daily expenses such as labor, electricity, and equipment maintenance. When sourcing internationally, transportation costs, tariffs, and customs clearance efficiency must also be considered. Understanding these cost components will help companies more accurately determine whether quotes are reasonable when negotiating with suppliers.

- ● Supply and Delivery Time:Stable supply capacity is crucial. If manufacturers lack effective inventory and production scheduling management, delivery delays can result, posing risks to the buyer.

- ● Flexible Minimum Order Quantity (MOQ):For small and medium-sized enterprises or those in the testing phase of new products, MOQ is a crucial consideration. Suppliers that offer low MOQs can help mitigate risk.

Are you looking for affordable polyester twisted yarn? You have come to the right place. We are committed to providing our customers with quality products and the best value. Your satisfaction is our motivation. Send an email to janekwok@xll-group.com today and our manufacturer will be happy to serve you.

|

Contact Us |

Email: janekwok@xll-group.com |

Whatsapp: +86-15980572980 |

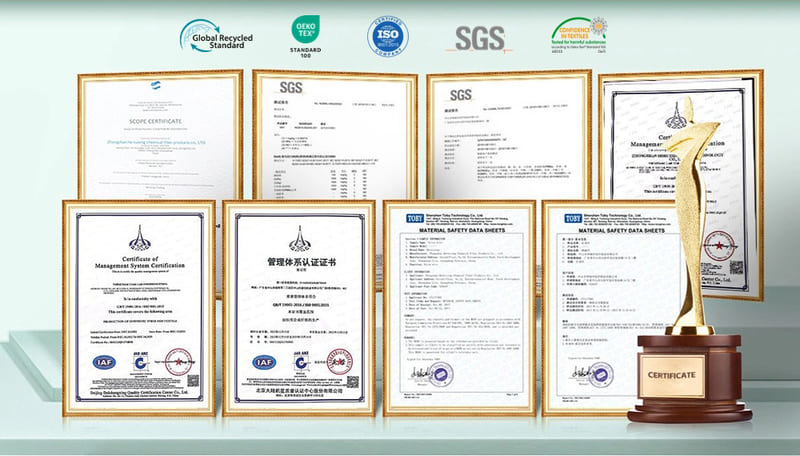

Certification and Compliance: Ensuring Supplier Authority and Credibility

Certification and compliance are crucial factors in assessing a manufacturer's reliability. When selecting a supplier, companies should consider whether they possess internationally recognized certifications and assess their credibility based on their actual business needs.

- ● Quality and Safety Certification: ISO9001 demonstrates that a manufacturer has a comprehensive quality management system, while Oeko-tex Standard 100 ensures that yarns meet international environmental and safety standards, making them particularly suitable for export markets.

- ● Environmental Compliance and Sustainability: With the increasing emphasis on environmental protection, suppliers' compliance with environmental regulations such as REACH and ROHS is crucial. Manufacturers with sustainable production capabilities (such as using recycled polyester) are more likely to be recognized by international buyers.

- ● Market Reputation and Customer References: Companies can assess a supplier's market reputation by examining their partner brands, customer references, and third-party audit reports. Manufacturers with established partnerships and a strong compliance record are generally more reliable and suitable for long-term partnerships.

How to Find Reliable Polyester Twisted Yarn Manufacturers in a Globalized World

In a globalized sourcing environment, companies face a wider range of options, but also greater challenges.

- ● Local vs. Global Sourcing: Local sourcing offers convenient communication and timely delivery, but can be more costly. International sourcing offers a wider product selection and cost advantages, but also requires addressing shipping times, tariffs, and cultural differences.

- ● Industry Exhibitions and B2B Platforms: Textile exhibitions are an important way to identify high-quality manufacturers. On-site samples and face-to-face interactions allow companies to quickly assess product quality and supplier capabilities. B2B platforms such as Alibaba and Made-in-China, as well as Google search keyword optimization, can also help companies quickly screen potential suppliers.

- ● Supplier Background Checks: Before finalizing a partnership, companies should verify the manufacturer's authenticity and capabilities through a combination of third-party audits, qualification verification, and on-site or video inspections. This effectively reduces procurement risks and ensures a reliable, long-term partner.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский