Sinrylion: Factory Advantages of Polyester Twisted Yarn Manufacturer

2025-08-01

Forty Years of Precision: Sinrylion's Manufacturing Heritage and Development Path

Founded in March 1983, Jinjiang Xinglilai Yarn Co., Ltd. (Sinrylion), a leading polyester yarn factory in China, has been deeply engaged in polyester yarn manufacturing for over four decades.

Headquartered in the Wuli Industrial Zone, Jinjiang City, Fujian Province, with registered capital of RMB 50 million, the group has grown steadily over the years to include several subsidiaries, including Dongguan Xinglilai Jingwei Yarn Co., Ltd., Quanzhou Xinxing Lilai Fiber Textile Co., Ltd., and the overseas subsidiary Vietnam Changsheng Fiber Industry and Trade Co., Ltd.

Currently, Sinrylion's customer base spans Fujian, Guangdong, Zhejiang, Hong Kong, Europe, and Southeast Asia, earning it a strong reputation. The company's high-quality products and stable delivery capabilities have earned the trust of clients across numerous industries, including textiles, ribbons, trademarks, and knitting.

In terms of manufacturing capabilities, the company boasts:

- ● Over 400 pieces of equipment, including core equipment such as POY spinning yarn, texturing machines, drafting machines, two-for-one twisters, and warping machines

- ● Approximately 200 of these twisters feature high speed, low noise, and stable operation

- ● Daily production capacity reaches 20 tons

- ● Annual output exceeds 2,000 tons of high-end polyester yarn and over 8,000 tons of standard polyester yarn

- ● Over 1,000 yarn varieties with vibrant colors, diverse lusters, and a full range of specifications are available

- ● Independent R&D and quality testing centers provide support for technological development and quality assurance

Sinrylion's success is not accidental; it is built on a long-term accumulation of scale, management, technology, and reputation. Forty years of manufacturing experience have laid a solid foundation for its status as a top-tier polyester twisted yarn manufacturer.

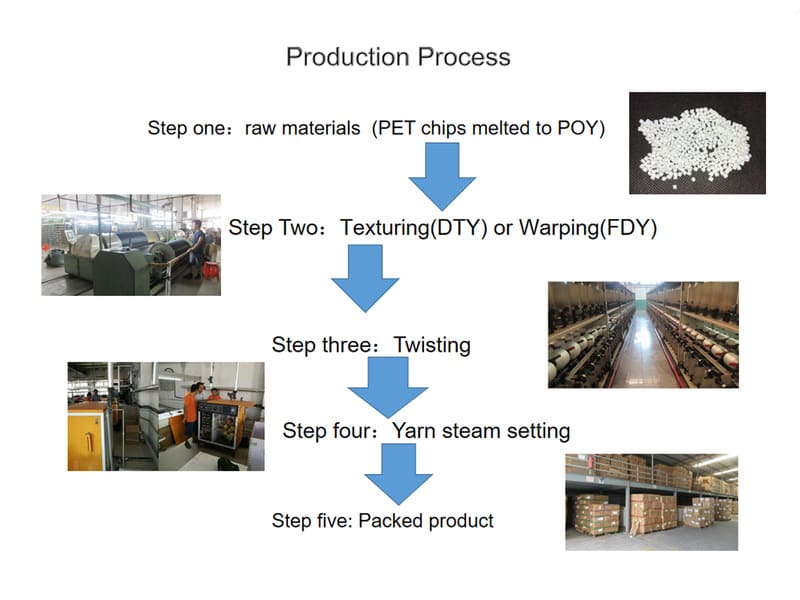

Efficient and Stable Manufacturing System: Modern Polyester Twisted Yarn Production Process

Sinrylion consistently adheres to the principle of "equipment is the primary productive force," continuously optimizing its production processes and introducing advanced manufacturing equipment to establish a complete and efficient polyester twisted yarn production process. This process is divided into five key steps.

● Pretreatment of Precursor Yarn: Laying the Foundation for Twisting

The raw material, primarily high-quality polyester filament (POY), undergoes texturing and drafting before entering the twisting process. This process, performed by a texturing machine, aims to increase the yarn's elasticity and stability, making it more suitable for subsequent processing.

Sinrylion's POY precursor yarn is sourced from a stable source, some produced in-house and some sourced from long-term suppliers, ensuring consistent quality and batch traceability.

● Two-for-One Twist Process Control: A Core Technology Embodying the Process

During the two-for-one twisting stage, Sinrylion's equipment supports twists ranging from 80 to 1000 t/m, encompassing conventional, high, and special twists. This meets the needs of polyester twisted yarn for various applications.

Twist direction can be selected in either S or Z directions, and the machine is equipped with an automatic twist adjustment function to ensure a compact product structure, uniform fiber structure, and uniform strength.

Products available:

- ● Semi-dull (SD) twisted yarn: soft and non-reflective

- ● Full-dull (FDY) twisted yarn: low brightness, suitable for high-end fabrics

- ● Bright twisted yarn: suitable for ribbons and lace

- ● Trilobal glossy yarn: strong three-dimensional effect, suitable for webbing and decorative fabrics

● Heat Setting: Locking Twist and Physical Properties

After twisting, the twisted polyester yarn requires heat setting to stabilize its physical properties. Sinrylion uses hot air furnace equipment, controlling the temperature between 130°C and 160°C. The heat treatment time is adjustable according to different specifications to ensure that the yarn does not loosen or deform during subsequent machine processing.

This process is crucial for twist rebound control, dimensional stability, and shrinkage resistance.

● Finished Product Winding: balancing efficiency and aesthetics

After setting, the yarn enters the automatic winding equipment. Sinrylion uses an electronic tension control system to prevent uneven tension from causing varying yarn tightness on the bobbins, which can affect product performance. Each bobbin is barcoded to ensure product traceability.

Finished product packages are uniformly sized for ease of subsequent use, transportation, and storage.

● Intelligent Warehousing and Shipping

After production, yarn is sorted and stored, and the system automatically allocates shipping plans. This information-based management of the entire logistics process improves delivery efficiency and accuracy. The company maintains a year-round safety stock system to ensure that large orders can be responded to quickly.

Quality is Competitiveness: A Comprehensive Analysis of the Multi-Level Quality Control System

- Raw Material Inspection Mechanism:Sinrylion implements a strict strategy for raw material control. Polyester filament used in twisted yarn production undergoes qualification review and technical evaluation before procurement. Upon arrival, batch inspections are conducted to ensure that indicators such as linear density, gloss, and moisture content meet standards. Only raw materials that pass these tests are put into production, ensuring consistent and stable yarn quality from the source.

- Real-Time Monitoring of the Production Process:During the twisting process, Sinrylion uses digital equipment to monitor twist and tension in real time to ensure that each yarn structure is uniform and tolerances are manageable. Twist tolerance is controlled within ±3%, with automatic feedback and adjustments from the system, combined with manual inspections, forming a dual-security mechanism. Each roll of finished yarn is assigned a unique tracking number for easy quality traceability and customer re-inspection.

- Finished Yarn Physical Property Testing:All finished yarns undergo testing at the testing center, covering core indicators such as twist, breaking strength, gloss, color difference, pilling level, and color fastness. Testing is conducted in accordance with GB/T and ISO standards, utilizing equipment such as electronic strength meters, colorimeters, and pilling testers to ensure that each batch of products possesses excellent physical properties and stable process compatibility.

- Authoritative certifications build trust:Sinrylion's ISO9001 quality management system, Oeko-tex Standard 100 ecological textile certification, and GRS Global Recycling Standard certification not only demonstrate that its products meet international environmental and quality standards but also demonstrate its execution capabilities and credibility as a professional polyester yarn manufacturer in the global market. These certifications further enhance customer confidence in the safety, compliance, and environmental performance of its yarns.

Are you looking for affordable polyester twisted yarn? You have come to the right place. We are committed to providing our customers with quality products and the best value. Your satisfaction is our motivation. Send an email to janekwok@xll-group.com today and our manufacturer will be happy to serve you.

Contact Us

Email: janekwok@xll-group.com

Whatsapp: +86-15980572980

Diversified Products: Adapting to the Practical Needs of Different Applications

Sinrylion understands that each industry has distinct yarn performance requirements. Therefore, we continuously develop and optimize our product range to become a truly versatile polyester yarn factory.

Our current product line includes:

● Polyester twisted yarn:Suitable for a variety of applications, including weaving, knitting, ribbons, and labeling, it features precise twist, stable color, and high weaving adaptability, making it our best-selling core product line.

● Recycled yarn and recycle twisted yarn:Compliant with GRS standards and made from recycled bottle flakes, it is energy-efficient and environmentally friendly. Widely used in international orders with sustainable sourcing requirements.

● Nylon twisted yarn:Providing excellent elasticity and softness, it is commonly used in stretch webbing, lingerie accessories, and functional fabrics.

● Diamond yarn, fancy yarn, monofilament, and blended yarn:These yarns offer decorative effects and are widely used in applications such as luggage trims, webbing, curtains, and apparel accessories, where color and appearance are of particular interest.

How to Identify a High-Quality Polyester Yarn Factory? Sinrylion's Five Tips

As a veteran company with 40 years of manufacturing experience, Sinrylion has summarized the following five practical indicators to help industry clients determine whether a factory is qualified for long-term partnership:

- ● Whether the equipment is systematic and whether its production capacity is sufficient:Newer machines are not necessarily better; rather, it depends on whether the factory can cover the entire process, including POY, DTY, two-for-one twisting, warping, and testing, and has a daily production capacity of over 20 tons.

- ● Whether a factory has an in-house testing laboratory:High-standard polyester twisted yarn production requires capabilities such as physical property testing and color fastness testing. Key factors include laboratory scale, equipment configuration, and transparency of testing standards.

- ● Whether the product supports traceability management:High-quality factories will create batch files for each batch of products, including raw materials, twist, heat setting parameters, and testing data, ensuring full process traceability.

- ● Whether it has obtained authoritative certifications and complies with international regulations. Certifications such as Oeko-tex, GRS, and ISO demonstrate the factory'sability to execute and deliver international projects in compliance.

- ● Whether it has industry experience and market reputation:Customer case studies, partner brands, and exhibition participation records can provide insights into the company's industry reputation and service level.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский