How Can Pet Monofilament Yarn Manufacturers Ensure the Quality of Mass-Produced Pet Monofilament Yarn?

2025-06-24

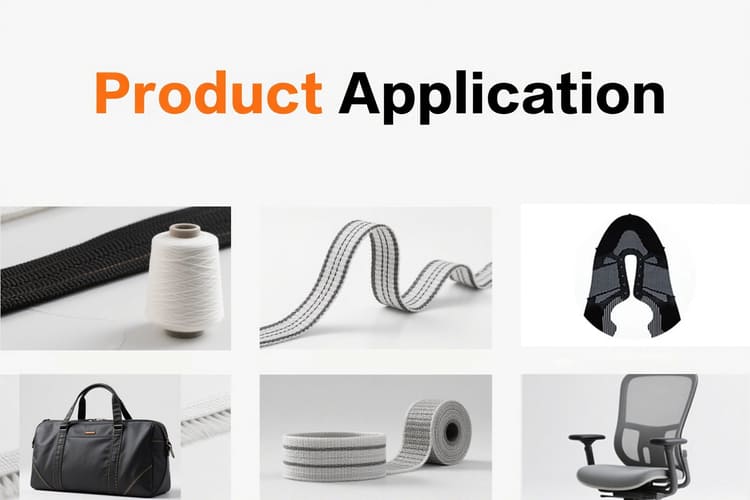

PET monofilament yarn is a polymer functional material widely used in industrial filtration, agricultural mesh, brush wire, webbing and other fields. With its good heat resistance, dimensional stability and mechanical properties, it plays the role of "invisible protagonist" in a large number of application scenarios.

However, unlike other bulk materials, the quality standard of PET monofilament yarn is not limited to strength and diameter. The uniformity, cleanliness, tensile properties, color stability and other dimensions of the yarn will have a key impact on the performance of the final product. Especially in the context of large-scale mass production, "stability" has become the core indicator for evaluating the quality control capabilities of manufacturers.

So, how does a qualified or even excellent PET monofilament yarn manufacturer ensure that the product quality is not discounted under the condition of high-capacity operation? This article will systematically analyze the four aspects of raw material control, process flow, quality management system and supplier selection.

Factors affecting the quality of PET monofilament yarn: From the source to the process, we cannot relax

Raw material purity

The quality of PET monofilament yarn depends primarily on the purity and stability of the raw material polyester chips. If the raw material contains impurities or recycled components, it will lead to an increase in the yarn breakage rate, uneven color, and even difficulty in subsequent dyeing and finishing.

At reliable manufacturers, pre-warehousing inspection of raw materials, drying process control and batch consistency management are the first line of defense for quality assurance.

Melt spinning process

During the spinning process, temperature, pressure, yarn speed and cooling conditions must be strictly controlled. Even a temperature fluctuation of 1°C may make some yarns too brittle or sticky. The uniformity and cleanliness of the yarn outlet also directly affect the surface finish and structural consistency of the finished product.

First-tier manufacturers often use multi-stage temperature zone control systems, combined with pressure sensors and self-cleaning spinnerets to ensure that the yarn output of each yarn is stable and reliable.

Production environment

Excessive humidity or the presence of dust particles in the air will cause burrs or particles on the surface of the finished yarn, affecting its subsequent application. High-quality manufacturers will maintain constant temperature and humidity production, and regularly clean equipment and floors to ensure the stability and cleanliness of the production space.

Key points of quality control in the manufacturing process: Grasping five points can stabilize the overall situation

Raw material pretreatment

Polyester chips entering the factory need to be fully dried and screened. The slices that are not completely dried are prone to hydrolysis during the melting process, which reduces the strength of the yarn.

Screening can remove particle agglomerates and powder impurities to prevent the spinneret from clogging.

Melt extrusion and spinning

The PET slices are heated to a suitable melting state through a multi-stage temperature control system, and then the melt is extruded through a high-precision spinneret. The diameter and distribution of each spinneret hole must be precisely consistent to ensure the consistency of the wire diameter.

The equipment accuracy, filter cleanliness and temperature stability used in this link are the key to determining the stability of the product.

Drafting and shaping

Drafting can improve the molecular orientation and increase the strength and elasticity of the yarn. Shaping "locks" the yarn structure through heating to improve dimensional stability.

Different uses require different drafting multiples. For example, industrial filter materials require higher strength, while brush wires pay more attention to rebound and flexibility. Manufacturers need to adjust process parameters according to product categories.

Winding and packaging

The tension control system ensures that the winding process is relaxed and does not knot or break. The finished products need to be packaged in moisture-proof and dust-proof packaging, and affixed with clear batch labels for easy traceability and storage.

How to choose a reliable PET monofilament yarn manufacturer? Five criteria that buyers must read

Faced with a large number of suppliers, how should buyers judge who is worth long-term cooperation? The following five standards are simple and practical:

- ● Advanced process equipment

- Does it have a spinning production line with a high degree of automation and digitization? Does it have tension control and constant temperature system? These directly affect the consistency and stability of the product.

-

- ● Quality control system

- Is there a dedicated quality inspection department? Has a full process record from raw material storage to finished product delivery been established? Can actual inspection reports be provided? A transparent and rigorous quality inspection process is an important basis for judging its credibility.

-

- ● Transparency of materials and processes

- Are you willing to provide raw material sources and compliance certificates (such as REACH, RoHS)? Does it support processing with supplied materials or customized specifications? This is related to the flexibility and compliance of cooperation.

-

- ● Cooperation resume and customer evaluation

- Have you ever served large terminal brands or export customers? Are there stable customers with a cooperation period of more than three years? These indicators are more convincing than "low price".

-

- ● After-sales and communication efficiency

- Is there a quick response mechanism? Can production progress tracking and abnormal handling solutions be provided? Faced with a large number of procurement needs, response speed and flexible services are equally important.

Are you looking for affordable PET monofilament yarn? You have come to the right place. We are committed to providing our customers with superior products and the best value. Your satisfaction is our motivation. Send an email to janekwok@xll-group.com today and our manufacturer will be happy to serve you.

|

Contact Us |

Email: janekwok@xll-group.com |

Whatsapp: +86-15980572980 |

Common problems and countermeasures: early prevention is the best solution

High wire breakage rate

Cause: spinneret hole blockage, melt instability, excessive drafting.

Countermeasures: Regularly clean the spinneret assembly; stabilize the extrusion temperature; optimize the draft ratio.

Different thickness

Cause: Uneven wire output, unstable cooling conditions.

Countermeasures: Adjust the cooling wind speed and angle; calibrate the spinneret hole position.

Obvious color difference

Cause: Inconsistent raw material batches, temperature control system fluctuations.

Countermeasures: Use the same batch of raw materials uniformly; calibrate the heating system temperature control sensor.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский