A Complete Analysis of the Application of Tpu Monofilament Yarn in Shoe Materials

2025-06-09

In the current era of rapid development of shoe material technology, traditional fiber materials can no longer fully meet consumers' multiple demands for comfort, durability, lightness and functionality. TPU (thermoplastic polyurethane) monofilament yarn, as a new polymer material with both elasticity and mechanical strength, is gradually becoming an important material choice in the shoemaking industry. Especially in sports shoes, casual shoes, outdoor shoes and other fields, TPU monofilament yarn is changing the traditional mode of design and production due to its excellent performance.

This article will deeply explore the material properties, typical application scenarios, performance comparison with traditional fibers, and application skills in shoemaking technology of TPU monofilament yarn, and put forward practical suggestions based on actual cases to help designers, purchasers and brands use this new material more efficiently and create high-performance shoes that meet market trends.

What is TPU monofilament yarn? Why is it changing the logic of shoe material manufacturing?

TPU monofilament yarn is a continuous monofilament fiber produced by high-precision extrusion, stretching and heat setting processes based on thermoplastic polyurethane. It integrates the flexibility of rubber and the strength of plastic, and has the following core features:

- Excellent elastic recovery ability: it can rebound quickly after stretching to maintain the shape and function of the shoe material.

- Strong wear resistance: much higher than ordinary polyester or nylon fibers, which can significantly extend the service life of the upper and supporting structure.

- Low temperature resistance and hydrolysis resistance: it can maintain stable performance even in wet or cold environments.

- Thermoplastic processing: suitable for a variety of modern shoemaking processes such as laser cutting, hot pressing, and hot sticking.

These characteristics enable TPU monofilament yarn to not only meet the needs of structural support, but also bring light, flexible and beautiful design effects, especially suitable for creating modern style and high-performance footwear products.

From upper to lining: precise application of TPU monofilament yarn in different shoe parts

TPU monofilament yarn is not only a functional material in footwear design, but also a medium for structural innovation. Its application runs almost throughout the entire shoe body, from the external support structure to the internal comfort system, and is specifically reflected in the following key parts:

1. Upper support structure

TPU monofilament yarn is often used in the uppers of sports shoes, running shoes and casual shoes. It is embedded in the knitted fabric as a support line or skeleton, which can significantly improve the structural stability and ductility of the upper. For example, Nike Flyknit and Adidas Primeknit uppers generally use TPU monofilament as a reinforcing yarn in high-strength areas, so that the uppers have excellent tensile and deformation resistance while maintaining lightness and breathability.

2. Shoelace hole area and edge reinforcement

In the shoelace hole area, TPU monofilament can reinforce the fabric by heat bonding or sewing, effectively dispersing the tension, avoiding fabric tearing, and improving durability. In some outdoor hiking shoes or training shoes, TPU monofilament fibers are also wrapped around the edge of the shoe mouth to strengthen the structural support and wear resistance of the edge area.

3. Tongue and lining fabric

Highly elastic mesh made of TPU monofilament is often used in the tongue area. It has good fit and is not easy to collapse. At the same time, TPU material does not absorb water, which is suitable for sports shoes, water shoes, etc. to wear in a humid environment, keeping dry and supportive. In addition, TPU yarn can also be used to construct a support layer in the heel pad area to replace the traditional foam structure and bring better rebound performance.

4. Insole support and arch skeleton

In some functional insoles, TPU monofilament is designed as a mesh or spring-like skeleton, which is wrapped in foam material, playing a dual role of shock-absorbing support and elastic enhancement. Especially in the application of the arch area, by adjusting the density and distribution of the monofilament yarn, it can provide a more ergonomic support structure and reduce plantar fatigue.

5. Side and heel stabilizer

In some high-performance footwear products (such as basketball shoes and football shoes), TPU monofilament can be made into a tight fabric or reinforcement layer and installed on the side or heel area of the shoe to help stabilize the foot's movement trajectory and prevent sprains. By coordinating with the TPU sheet on the sole, a complete force conduction channel can be constructed to improve sports performance.

The braidability, plasticity and high strength characteristics of TPU monofilament yarn have systematically improved its application in various structural parts of shoe materials, which not only improves the wearing experience, but also provides more possibilities for brands in terms of appearance design, lightweight and high performance.

Performance comparison analysis: Which is better, TPU monofilament yarn or traditional materials?

From the comparison of actual performance data, TPU monofilament yarn outperforms traditional shoe fiber in multiple dimensions:

|

project |

TPU monofilament yarn |

Nylon (PA6) yarn |

Polyester (PET) yarn |

|

Tensile Strength |

high |

Medium to high |

middle |

|

Elastic recovery rate |

Very high |

middle |

Low |

|

Wear resistance |

Very high |

high |

middle |

|

Hot working suitability |

excellent |

generally |

generally |

|

Environmental stability |

Excellent (moisture resistant, low temperature resistant) |

Easy to absorb moisture |

Moisture resistant but poor elasticity |

TPU monofilament yarn has obvious advantages in the three dimensions of "high rebound, strong support, and thermal adaptability", making it more suitable for the design and functional requirements of modern high-end shoes.

New Trends in the Footwear Industry: Forming, Processing and Technical Practice of TPU Monofilament Yarn

With the popularization of intelligent manufacturing and high-end shoemaking equipment, the processing methods of TPU monofilament yarn have gradually diversified, mainly including:

Hot Press Lamination Technology:It can be compounded with the upper fabric through hot melt adhesive to provide a functional area with a smooth surface, which is used for LOGO, lines or structural reinforcement.

Seamless Weaving Whole Shoe Technology:Compatible with knitting processes such as Flyknit and Primeknit, TPU monofilament can be accurately implanted as a support line to achieve a one-piece high-performance upper.

Laser Cutting:TPU monofilament mesh can be accurately cut by laser equipment to keep the edges clean, suitable for complex patterns and multi-layer structure designs.

3D Printing Shoe Material Skeleton:Combined with the hot melt plasticity of TPU monofilament, it may be possible to cooperate with 3D printing technology in the future to develop personalized support structures and functional modules.

Are you looking for cost-effective TPU Monofilament Yarn? You have come to the right place. We are committed to providing excellent products and offering the best value to our customers. Your satisfaction is our motivation. Send an email to janekwok@xll-group.com now, our supplier is dedicated to serving you.

Contact Us

Email: janekwok@xll-group.com

Whatsapp: +86-15980572980

Purchase Guide: How to Choose TPU Monofilament Yarn for Your Shoe Material Needs?

It is very important to choose the appropriate TPU monofilament yarn parameters for different shoe styles and functional requirements. You can refer to the following dimensions:

1. Diameter/denier

Fine denier yarn is suitable for lightweight uppers; coarse denier yarn is suitable for structural support layers. The common range is between 20D and 100D, and designers can match it according to the style of the shoe.

2. Hardness (Shore A)

The hardness of TPU itself is adjustable. Monofilaments of different hardness correspond to different elasticity and support. The common TPU monofilaments used for shoe materials are between Shore A80 and 95.

3. Color and gloss

TPU monofilaments can be made into transparent, matte, high gloss and other surface effects to meet the visual design requirements of different styles of shoes.

4. Processing adaptability

It is necessary to ensure that the selected TPU monofilament is suitable for shoemaking processing requirements such as hot pressing, knitting, and hemming to avoid material loss due to process mismatch.

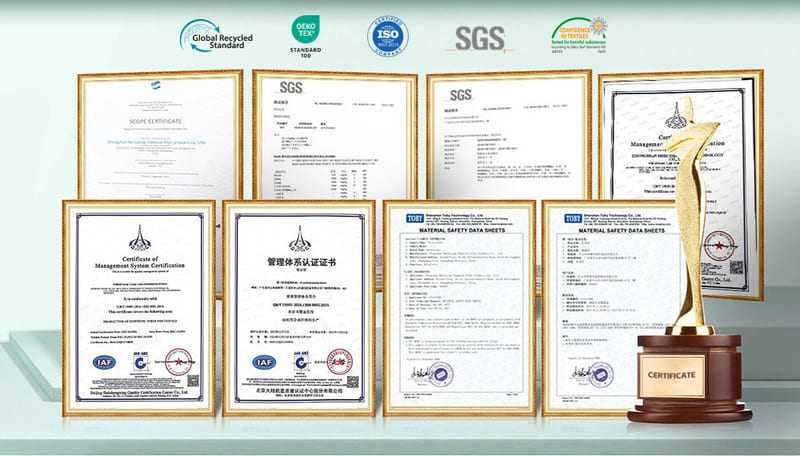

5. Certification and environmental standards

It is recommended to choose TPU monofilament yarn that has passed OEKO-TEX, REACH, RoHS and other international standards certification to ensure the environmental protection and sustainability of the product.

English

English 한국어

한국어 বাংলা ভাষার

বাংলা ভাষার हिन्दी

हिन्दी Türkçe

Türkçe русский

русский